Application Areas:

≤10mm

Application Areas:

≤10mm

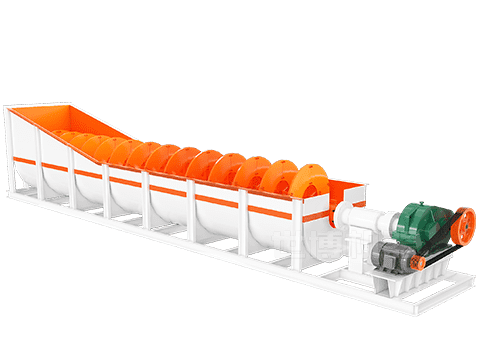

The spiral sand washing machine can clean and separate the soil and debris in the sand and stone. Its novel sealing structure, adjustable overflow weir plate and reliable transmission device ensure the effect of cleaning and dewatering. It is widely used in washing, grading and impurity removal of highway, hydropower, construction and other industries, as well as the washing of fine-grained and coarse-grained materials, especially suitable for construction and road construction. Spiral stone washing machine is used for desliming and screening of a large amount of sand and stone used in construction sites, sand and gravel factories, prefabrication plants and hydropower construction sites, and also for ore dressing. It can effectively handle materials within 0-30mm, and can separate the soil and ash powder on the materials into clean materials. This machine has the advantages of simple structure, easy maintenance and high washing efficiency. Spiral sand washing machine is divided into double screw and single screw. Compared with the single screw sand washing machine, the double screw stone washing machine has the advantages of high efficiency and large output, and can handle materials within 0-30 mm.

Spiral sand and stone washing machine has low power consumption and high cleaning degree. Good sealing structure, fully enclosed transmission device and adjustable weir plate ensure the high efficiency and durability of the product, good cleaning and dewatering effect, and stable fine-grained products.

The crushed and graded materials in the early stage of customers enter the front-end double screw sand washing device. After the graded cleaning, the qualified materials enter the tail end dry discharge device for dehydration. The residual waste water (including some qualified materials) after cleaning in the spiral sand washing device enters the rear storage tank through the overflow device, and then is pumped into the separation and recovery unit. Under the action of centrifugal force, it is classified and concentrated and then closed The materials in the grid enter the tailing dry discharge device for dehydration, and the rest of the wastewater enters the backwater device for discharge.

| model | Screw diameter (mm) | Tank length (mm) | Feed size (mm) | Screw speed (R / min) | Production capacity (T / h) | Power (kw) | Water consumption (T / h) | Overall dimension (mm) |

| XL515 | 515 | 7615 | ≤10 | 38 | 5-15 | 5.5 | 6-60 | 8100X2345X1450 |

| XL765 | 765 | 7620 | ≤10 | 26 | 20-60 | 11 | 9-63 | 8545X2650X1870 |

| XL920 | 920 | 7585 | ≤10 | 100 | 40-110 | 11 | 10-80 | 8500X2100X3600 |

| 2XL920 | 920 | 7585 | ≤10 | 200 | 80-220 | 2X11 | 20-160 | 8420X3760X3960 |

| XL1120 | 1120 | 9750 | ≤10 | 175 | 50-130 | 18.5 | 20-150 | 1078X3980X4170 |

| 2XL1120 | 1120 | 9750 | ≤10 | 350 | 100-260 | 2X18.5 | 40-300 | 1097X5250X4720 |

Thank you for your interest in Zhengzhou BooRant machinery Equipment Co., LTD. If you want to know more about our crushers and industrial grinding equipment.

Contact us now to find out what we can do for you!

Zhengzhou BooRant machinery Equipment Co., LTD is a professional high-end equipment manufacturing enterprise integrating R&D, production and sales. Its business scope covers sand and gravel aggregates, industrial grinding powder, mobile crushing plant, EPC general contract project and other professional high-end equipment manufacturing enterprises.